[ad_1]

Various SMEs, such as those in the automotive, rubber and plastics, and food and beverage industries, are using the advantages of cobots, such as cheaper costs and ease of programming and integration.

Various SMEs, such as those in the automotive, rubber and plastics, and food and beverage industries, are using the advantages of cobots, such as cheaper costs and ease of programming and integration.

Fremont, CA: Today’s industrial columns are progressively being transformed by robotics. It has ushered in a sea change as businesses turn to it to increase productivity while reducing the burden on human workers and employees. Based on current industrial trends, this industry will also see exciting trends that could transform the way the world operates today. While robotics has effectively altered manufacturing industries in recent decades, it will expand beyond assembly line areas in the coming years. Here are four robotics trends to look out for:

Cloud Robotics:

Robots are no exception to the rule that all technologies are interconnected. Robots in connected infrastructure and shared services environments will benefit from current data centers’ tremendous computing and storage capabilities thanks to cloud robotics. Even RaaS models can connect actual robots to cloud-based administration and analytics services. The robots will be easier to monitor, manage, and maintain remotely thanks to cloud connections.

Robots-As-A-Service (RaaS):

RaaS business models will acquire a lot of traction as firms rush to digital transformation and strive for innovation. Through virtual agents, these robotics models enable firms to execute repetitive and challenging tasks in less time. This helps businesses to cut operational costs and reduce upfront investments in high-value, high-demand business operations. RaaS also provides rental and leasing services, expanding the global robotics rental market and lowering the cost of permanent deployment options.

Cobots:

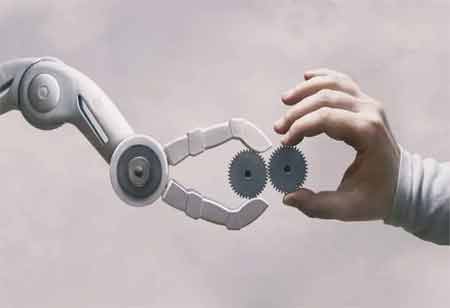

It’s a combination of the words “collaborative robot” and “robot.” This branch of robotics exemplifies the belief that autonomous machines would supplement rather than replace human labor. They will provide prompt support whenever we require it. Various SMEs, such as those in the automotive, rubber and plastics, and food and beverage industries, are using the advantages of cobots, such as cheaper costs and ease of programming and integration. We now have cobots with significant payload capacity and range.

Machine Learning in Robotics:

Machine vision is critical for robotic systems. Robots with cameras can tackle difficult tasks and ensure that the desired action is carried out correctly, while machine vision algorithms handle image analysis. Vision guiding systems can let robots recognize objects and feel their surroundings, allowing them to move without stumbling over obstacles. And this functionality will become increasingly popular in all robotic applications soon. As a result, processes such as packaging, shipping, assembly, and quality control may now be completed more effectively by robots.

See Also: Top 10 Bioinformatics Solution Companies

[ad_2]

Source link

Leave A Comment

You must be logged in to post a comment.